PROJECT BRIEF

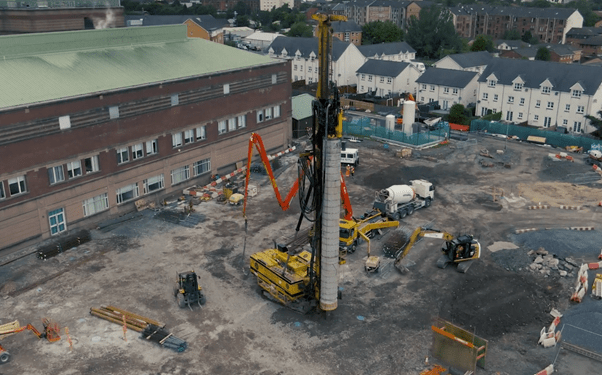

Roger Bullivant Limited was employed to install 443 piles required to support Project 2 at the Golden Jubilee National Hospital, Clydebank on behalf of Kier Construction Scotland and NHS Scotland.

Project 2 will deliver additional theatres for orthopaedic surgery, a day case/day surgery admission unit, supporting accommodation, an outpatient/pre-operative assessment area and diagnostic space.

It will have a footprint of around 2830 square metres, with a gross floor area of 8000 metres over three floors.

According to published plans, level one will include medical physics and sterilising departments, level two will contain surgical admissions and endoscopy facilities, while level three will house theatres and operating facilities.

Staff facilities, patient admission and discharge space, offices and clinical support facilities will be included.

KEY ISSUES

RBL was required to provide a design methodology to suit the underlying ground conditions using both information provided by the Client, along with our local knowledge and extensive experience working in the area. The ground conditions comprised an upper covering of made ground, overlying soft and firm silty clay underlain by medium dense to dense and very dense gravelly sand.

Several piles were located in close proximity to the existing hospital building, which was to remain fully operational for the duration of the works. Again, this prompted consideration over piling technique to ensure minimal disturbance to patients and staff during our time on site, and to prevent damage to surrounding structures.

The site was located within a Naval Construction Works shipyard during WWI and WWII, and examination of WWII air raid bombing records suggested that numerous exploded and unexploded High Explosive (HE) bombs affected Clydebank Burgh (the location of the site). Statistics obtained from the National Archives indicate the area sustained an overall very high density of bombing, with an average of 170.8 bombs recorded per 1000 acres. As such the site was classed as having ‘medium risk’ of unexploded ordinances (UXO), and risk mitigation methods were required prior to commencing work.

SOLUTION

RBL installed our 300/600mm dia Continuous Helical Displacement (CHD) piles to varying depths for compression loads up to 815kN and 400/700mm dia Continuous Helical Displacement (CHD) piles to varying depths for compression loads up to 1077kN. Due to the core pile layouts within the structure, we opted for our 450/750mm dia Continuous Helical Auger Displacement (CHAD) piles to varying depths for compression loads up to 1275kN. Maintained load testing of piles returned excellent results, well within tolerances set by Project Engineer.

The CHD pile was selected as it generates negligible levels of noise and vibration and creates no appreciable arisings meaning there is minimal spoil to remove from the site. The pile is formed using a highly efficient multi-flight bullet ended shaft, driven by a torque rotary head, enabling penetration of the strata without bringing material to the surface. Data is recorded using computerised instrumentation. Nominal surface heaving may occur but compared with the arisings from CFA boring, the volume is negligible.

The CHAD pile is formed similar to a standard CHD pile, is a bored pile that displaces the soils through which it is constructed. The pile is formed using a highly efficient multi-flight bullet-ended shaft, driven by a torque rotary head, enabling penetration of the strata without bringing material to the surface. Data is recorded using computerised instrumentation. Should ‘lock out’ be experienced within any dense alluvial deposits prior to reaching design depth, the CHAD pile can pre-auger ahead of the bullet ended shaft to ensure penetration beyond such in order to advance pile to design depth. The maximum design depth of the CHAD system is 15.0m. Once drilled to design depth, concrete is pumped under pressure down the hollow shaft to the boring head and out of the tip while the shaft is reverse rotated and

withdrawn from the bore. Reinforcement in the form of a cage and single bar is introduced into the bore upon completion of the concreting operations. The spoil is removed up the auger within the casing and extracted at the top of the pole. The CHAD drilling system is enclosed within a shroud to ensure the spoil arising are removed in a controlled manner.

To overcome any issues regarding the densification of the soils within the core groups and to ensure penetration to design depth we opted to base our design for the core piles on 450/750mm CHAD. The CHAD system consists of a multifunctional boring head, this comprises an outer casing which houses an internal auger 350mm diameter CFA auger. The external casing retains the CHD bullet’s profile with a 450mm diameter core and 750mm diameter flight. The CFA auger can be advanced ahead of the CHD-type boring head to release ground pressure through overconsolidated soil layers.

Kier Construction Scotland arranged for intrusive magnetometer surveys of all pile locations extended to the maximum bomb penetration depth. The results of the report confirmed all proposed pile positions were free from UXOs and works could commence on programme.

Upon commencement of piling operations, it was concluded that the dense granular strata were encountered at circa 7.0mbgl at the north end of the site, increasing in depth to circa 10.0mbgl towards the south end of the site. As such pile design lengths ranged from 8.0m to 12.0m and all piles were installed subject to torque drilling resistances.