CDA

PILES

RBL has pioneered an innovative cast in situ displacement piling solution, introducing Continuous Displacement Auger (CDA) piles as an alternative to conventional CFA piles and an iteration of our Continuous Helical Displacement (CHD) pile. This technique represents a more practical and cost-effective approach for a diverse range of construction projects.

CDA piles stand out as straight-shafted bored displacement piles, distinguishing them from traditional auger techniques. Due to the displacement effects, one of the most notable advantages of CDA piles is their ability to deliver superior capacity when compared to traditional auger methods of comparable geometries. This enhanced load bearing capacity often enables shorter piles to be installed in comparison to traditional CFA techniques.

Furthermore, CDA piles contribute to a more sustainable construction process by generating minimal spoil, aligning with environmental considerations, and reducing the need for removal of waste off site. In essence, RBL's CDA piles showcase a forward-thinking approach, combining efficiency, cost-effectiveness, and sustainability. The innovation in this piling solution makes it a compelling choice for projects seeking enhanced performance and minimal environmental impact.

WHAT THEY’RE USED FOR

CDA piles offer a versatile and practical solution for a range of construction projects, particularly those with light to moderate load requirements, typically up to 500kN. This adaptability positions CDA piles as an ideal choice for various structures and applications, providing reliable support within this load range.

CDA piles prove effective in navigating through different soil types, including stiff clays, silts, and loose granular soils. This versatility ensures that the piles can be deployed in diverse geological conditions, contributing to their applicability across a variety of construction scenarios. The ability to function effectively in these soils underlines the flexibility and efficiency of CDA piles, making them an asset for projects seeking a reliable foundation solution with moderate load-bearing requirements.

THE PROCESS

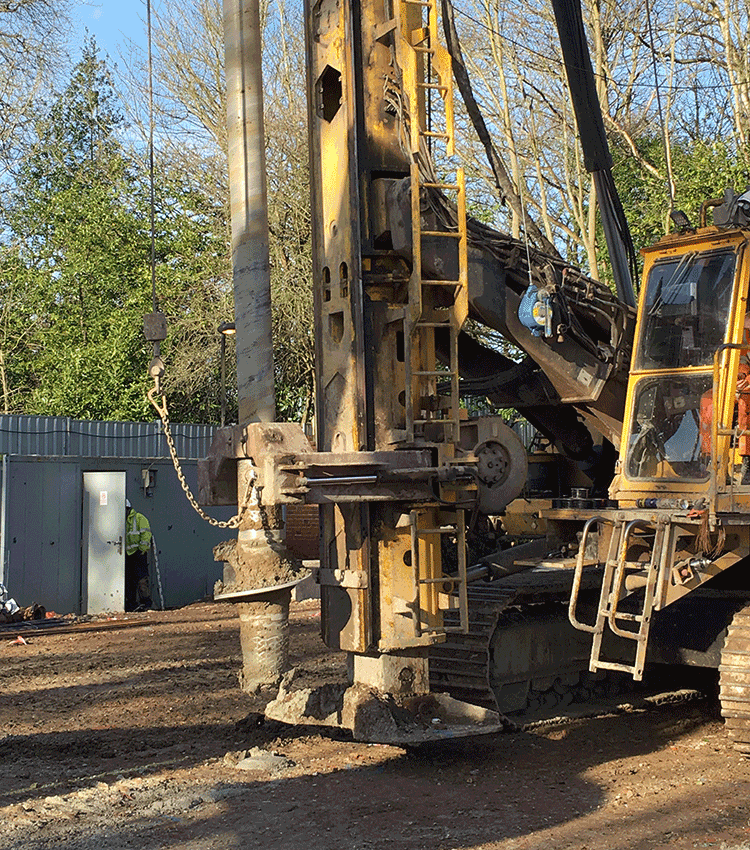

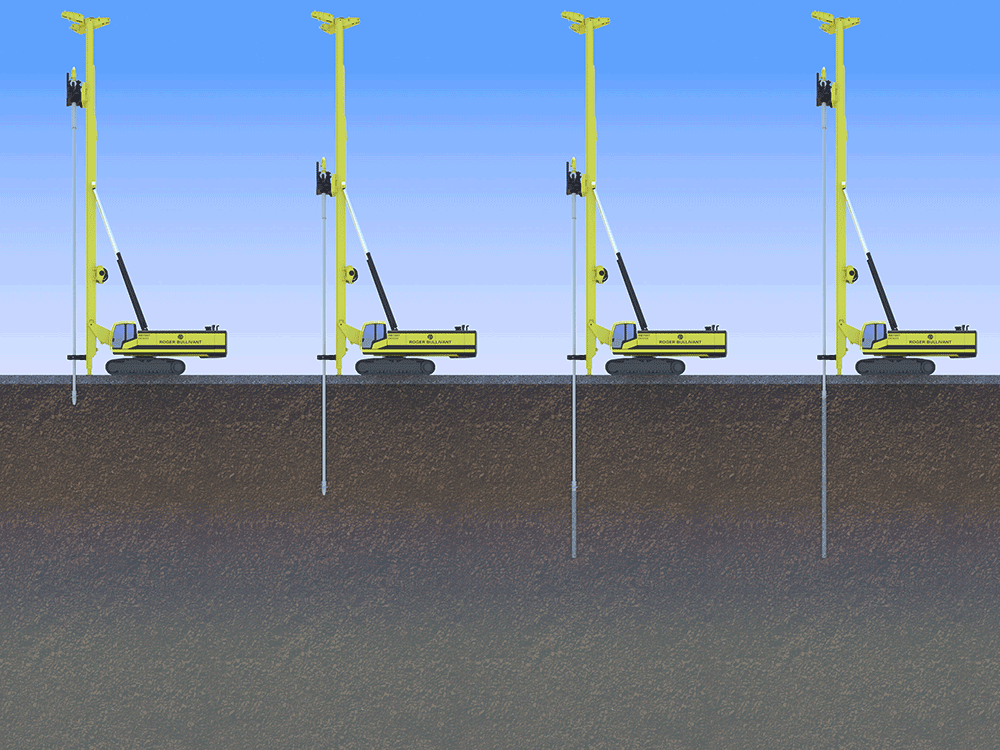

The installation process is orchestrated with precision, commencing with RBL's bespoke displacement tool. This tool, expertly designed and calibrated by the experienced Design Engineering team, penetrates both the working platform and the underlying soil to a pre-determined design depth.

Once drilled to a calculated or proven depth, concrete is pumped under pressure down the hollow shaft to the boring head, and out the tip while the shaft is reverse rotated and withdrawn from the bore, ensuring a uniform and structurally sound foundation. To complete the process, surface heave and waste concrete is cleared from the formation prior to the introduction of the required reinforcement. This thorough approach, coupled with the integration of advanced technology, guarantees the construction of high-quality piles that adhere to the precise specifications set forth by RBL.

WHY USE CDA Piles?

- Manufactured in-house, ready for immediate dispatch

- Quiet installation

- More efficient and cost-effective

- Shorter piles to achieve required loadings

- Quicker installation

- Reduced spoil compared to traditional CFA piling

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.