DRIVEN TUBULAR

STEEL PILES

Driven Steel Tubular Piles offer a robust foundation solution with enhanced driving capabilities and reusing steel casings sourced as waste from the oil and gas industry.

They serve as an alternative to Driven Precast Concrete Piles, particularly in situations where challenging driving conditions or uncertain ground conditions are expected. Their strength, adaptability, and sustainability benefits make them a practical choice for a wide range of projects and locations across the UK.

WHAT THEY’RE USED FOR

Driven Steel Tubular Piles play a crucial role in supporting foundations in a variety of structures, spanning residential, commercial, industrial, and heavy civil works sectors. They are perfectly suited to address challenging ground conditions found across the UK, for example, dense made ground, banded natural strata, or where keying into rock is required and these piles emerge as a versatile solution in these complex situations, where issues could occur with other pile types.

Driven Steel Tubular Piles are a displacement solution, so do not generate soil arisings during installation, an essential requirement where ground may be contaminated, as well as for general use to remove the need for disposal of waste soil and reduce associated traffic movements and cost.

Driven Steel Tubular piles can be designed to cater to a range of different types of loading, including compression and shear, and come in a variety of sizes and wall thicknesses to allow selection of the most suitable product during the design stage. They are predominantly used below pile caps, beams, and slabs and are also a perfect partner to our Precast Beam System.

Whether dealing with difficult ground conditions or addressing contamination concerns, these piles provide a solid foundation for many structures across all sectors. They are robust so can be employed where more difficult driving conditions could damage Driven Precast Concrete Piles.

THE PROCESS

Driven Steel Tubular Piles offer quick installation on site and for follow on works. They are typically installed as open-ended (although an end plate can be installed on the lead section if necessary) and often do not need to be concreted for design purposes. They are immediately ready for subsequent construction phases. Commonly follow-on trades will concrete and install starter bars to the hollow pile following cropping down to cut-off levels. Additional reinforcement can be easily introduced if required by design given the hollow nature of the sections, for example, tension bars.

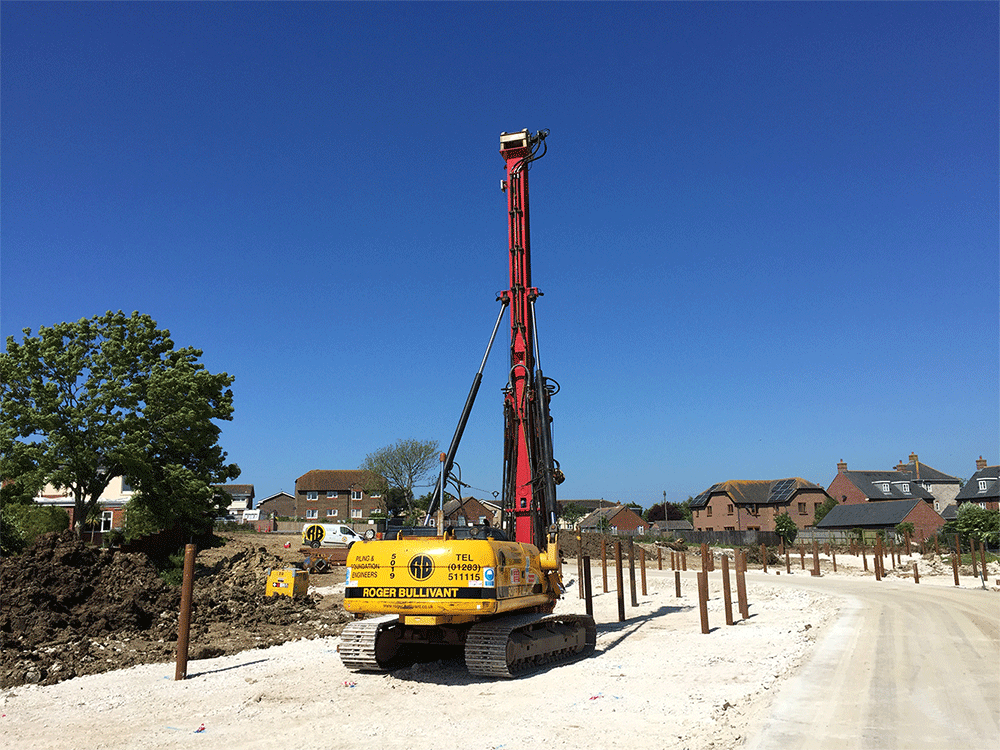

Driven Steel Tubular piles are efficient to install. They are driven into the ground by RBL's in-house top driven rigs, specifically designed with hydraulic hammers weighing between 3 and 6 tonnes. The synergy between the hammer weight and piling rig design itself is geared towards achieving low bearing pressures for reduced working platform thicknesses compared to ‘off the shelf’ driven piling rigs, and also for increased production rates on site.

The piles are supplied to site in segmental lengths typically ranging from 3m to 6m. The lead section is pitched and driven, and subsequent sections are added, being tailored to suit required depths, and minimise material wastage. Pile installation progresses to a design length or a set/refusal to suit the ground conditions and loading requirements of the individual scheme.

By their nature Driven Steel Tubular Piles have flexibility in adapting to varying ground conditions. The result is a clean, rapid, and effective installation that sets the stage for seamless progress in subsequent construction phases, re-using a material that is otherwise classified as waste.

WHY USE Driven Steel Tubular Piles?

Environmentally friendly

Quick installation

Robust piling solution

Minimum site preparation

Extensive range of pile sizes

No spoil or wastage

Pile stability in sloping rock conditions

EXAMPLE Driven Tubular

steel piling PROJECTS

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.