SECTIONAL FLIGHT

AUGER (SFA) PILES

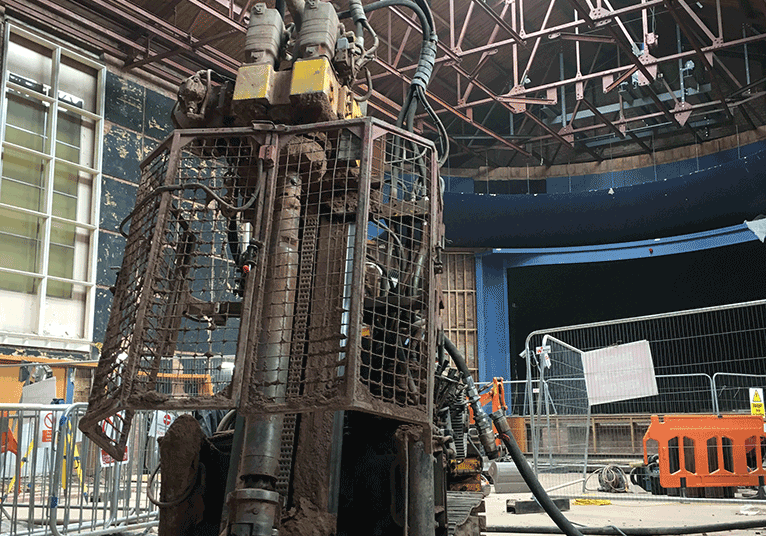

Sectional Flight Auger (SFA) piling is an auger bored replacement pile solution for restricted access piling which provides the ability to install piles in low headroom or restricted-access sites.

SFA piling offers a similar solution to CFA piling, except the auger is made up of shorter sections of hollow stem continuous flight auger.

WHAT THEY’RE USED FOR

SFA piling excels in unobstructed conditions encompassing various soil types, including made ground, clay, weak rock, gravel, glacial till, and areas with high water tables. Its adaptability to such diverse substrates underscores its efficacy in accommodating the geological variability often encountered in construction projects.

In urban environments or confined spaces where conventional equipment may struggle to operate, SFA piling offers a practical and efficient alternative. Its segmented auger design enables precise drilling and pile installation in tight spaces, mitigating the challenges posed by restricted access or overhead obstructions.

The versatility of SFA piling extends beyond geological considerations to encompass logistical and environmental factors. Its ability to navigate through various soil types and challenging site conditions while maintaining operational efficiency makes it a preferred choice for projects where adaptability, performance, and reliability are paramount.

In summary, SFA piling stands as a versatile and adaptable solution capable of addressing a broad spectrum of site-specific challenges, making it an indispensable tool in modern construction projects where restricted access, limited headroom, and diverse soil conditions present formidable obstacles.

THE PROCESS

SFA piles represent a cutting-edge foundation solution that leverages sectional hollow-stemmed augers to create robust and reliable support to structures. This innovative technique offers numerous advantages across a range of ground conditions, making it a preferred choice for projects where precision, efficiency, and performance are paramount.

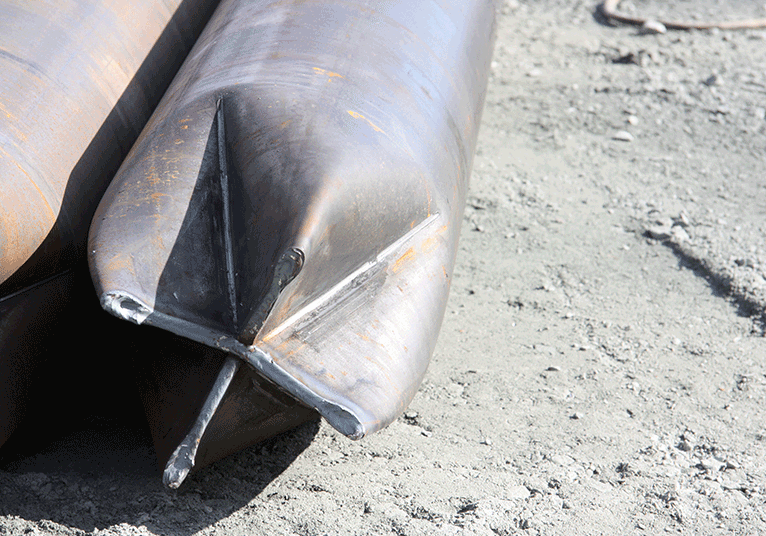

The process begins with the deployment of a sectional hollow-stemmed auger, which is inserted into ground to create boreholes tailored to project specifications. As the auger penetrates the ground, it generates arisings, effectively clearing the borehole and facilitating smooth operation in most ground conditions.

Once the borehole reaches the designated depth, the next phase involves the injection of concrete or grout through the hollow stem of the auger as it is gradually withdrawn maintaining a head of concrete or grout. This simultaneous process ensures that no voids are formed during the auger extraction, creating a solid and stable pile. On completion of the pumping operation the insertion of reinforcement further enhances the structural integrity and load-bearing capacity of the pile.

WHY USE SFA Piles?

- Fast, quiet and virtually vibration-free

- RB in-house purpose-built rigs

- Quiet installation compared to other methods of piling

- Suitable for most ground conditions

EXAMPLE SECTIONAL FLIGHT

AUGER (SFA) PILing PROJECTS

ROGER BULLIVANT

QUALITY CONTROL

We successfully deliver projects to the highest standard, safely, on time, within budget, and with care for the environment and communities. Clients choose RB time and time again thanks to our proven track record.

All products are manufactured to BSEN, ISO, and CE accreditation. We are committed to ensuring we continuously deliver high quality, robust service, and product to our clients. At RB we continuously review and access where we can further improve.

We are proud to be recognised and awarded the RoSPA gold award for the sixth year running for the exceptionally high standards towards the health and safety of our employees.