CLIENT

McLaren

SCOPE OF WORKS

ACHIEVEMENTS

Rapid resolution of onsite changes

Collaborative design development with Client and Engineer

PROJECT BRIEF

McLaren Construction was appointed by the UK’s leading self-storage operator Big Yellow Self Storage to complete an exciting new facility in Hove, East Sussex.

Over the past two decades, McLaren has delivered sixteen Big Yellow storage facilities, the first being a self-storage unit in Finchley, North London back in 2002, and since then the partnership has evolved to build over 1 million square feet of self-storage and office space together across the UK.

RB was contacted about developing a suitable solution for the piling of this prestigious project.

KEY ISSUES

Details of systems adopted, types of pile, depths, loads etc.

RB proposed Continuous Flight Auger (CFA) piling for all piles.

The project comprised of a two-story basement. A contiguous piled wall was best suited due to the groundwater table being below the excavation level.

RB provided a design methodology to suit the underlying ground conditions with the sequence of strata compromising of 6m of made ground over chalk.

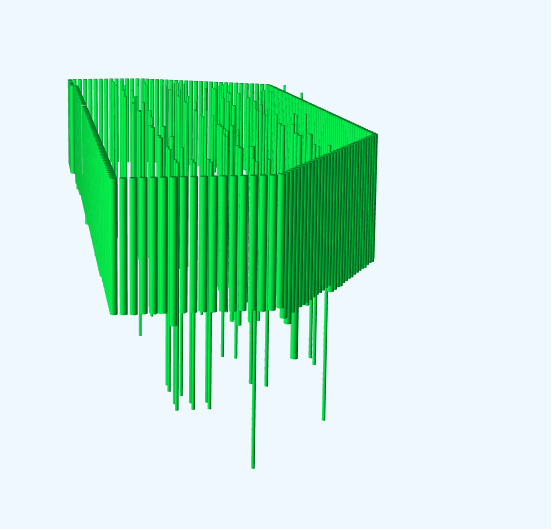

RB’s scope included 247no. 600mm dia CFA contig wall piles to depths of up to 12m, 123no. bearing piles to depths of 22m, and 13no. 450mm crane base piles to 25.5m.

SOLUTION

This logistically challenging site needed detailed planning which was agreed with McLaren’s Project Management team prior to the arrival of RB’s Entico 7007 65 tonne rig.

For the piled retaining wall RB explored both a propped and unpropped design, with McLaren opting for the unsupported cantilever option removing the requirement for temporary works propping and bracing which alleviated any restrictions when excavating the 6m dig. This approach accelerated the programme for basement construction.

Pile sequencing was discussed and agreed with the client prior to mobilisation, this considered the site constraints, two piling platform levels and other trades. Communication and management of our supply chain was critical, to ensure that the delivery of fourteen differing prefabricated cage types did not affect site productivity when considering the available site storage space.

RB encountered several unknown obstructions while installing the contiguous wall piles, these obstructions were thought to be piles from the previous building. RB acted quickly and engaged with the client engineers to explore solutions to overcome these challenges. RB proposed two suitable options which mitigated the impact on the current design and construction methodology to the basement liner wall.

RB employed the use of its in-house digital twin software to effectively manage the construction sequence and ensure the project was delivered with the highest of quality.

RB worked closely with the McLaren site team ensuring the timely delivery within the 30-day programme.

Project Manager, McLaren said,

“RB delivered on programme, quality and budget and overcame unforeseen issues efficiently. I look forward to working with you again.”