PROJECT BRIEF

Roger Bullivant Limited (RBL) provided a piling solution for Oakland Homes’ residential development in Arundel. Initially, the client sought a traditional Continuous Flight Auger (CFA) solution, but due to contaminated ground, RBL suggested and successfully executed a Continuous Helical Displacement (CHD) piling solution.

This not only mitigated risk of exposure to the contaminated ground, but also addressed the site’s challenges, eliminating the need for costly and environmentally unfavourable spoil removal.

KEY ISSUES

There were two different piling platform levels (PPL): 4.7m AOD for Block A and 2.1m AOD for Block B. High piling platform level and low cut-off levels on Block A resulted in the design of longer piles with long debondings.

The site is situated near River Arun, where tidal movements take place. The highest water level recorded for the River Arun was 3.65m AOD, which is in line with the existing ground level at the Arundel site.

Historically, a town gas works was operational on the site from the 1840s until the mid-20th century. Ground investigation reports revealed contamination across the site but concentrated in the northern portion. Groundwater was also impacted by the contaminants.

An existing substation was located in the centre of the proposed location of Apartment Block B. This was planned to be deactivated and removed, but the client was not able to do this until the end of the piling operation.

A live gas pipeline was located under the adjacent Ford Road, with proposed piles within 5 metres. An agreement for displacement piling was made with the local authority before the execution of CHD piling.

SOLUTION

- 54% of the piles were from the higher PPL, resulting in longer piles and debonding. A value engineering proposal to reduce the PPL resulted in the coverage reducing from 54% to 14%. Material and cost savings for the piling were achieved on 40% of the piles.

- The utilisation of CHD piles eliminated the need to dispose of 737m3 contaminated soils.

- A CHD solution resulted in shorter pile depths in comparison to CFA, making it a more cost-effective solution. An advantage when working close to the existing substation and gas mains.

- Despite the challenges, the project was completed successfully through careful planning, problem solving and execution. The project highlights the importance of thorough planning, effective design, and collaborative efforts in accomplishing project objectives.

- Moreover, the successful completion of the project reinforced RBL’s reputation as a competent and dependable service provider. The project serves as a remarkable achievement, attesting to the team’s ability to overcome obstacles and deliver exceptional results.

SUSTAINABILITY

- The CHD piling option was decided to be the best option over CFA, CDA, and Driven Precast Concrete Piles based on the ground conditions, high loadings, and sustainability concerns.

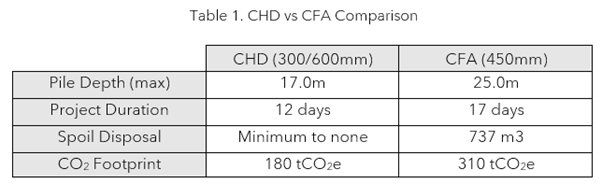

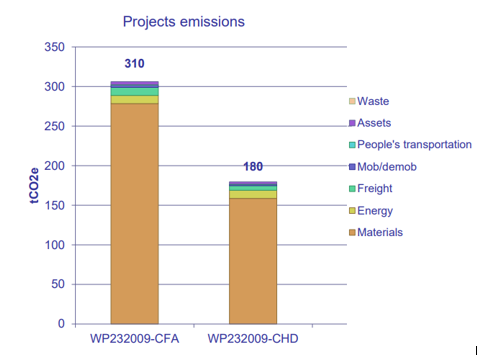

- The CHD (300/600mm) piles offer a pile depth of 17.0m and a project duration of 12 days. These piles also win recognition in environmental sustainability with reduced CO2 emissions compared to CFA (450mm) piles, which have a greater pile depth of 25.0m, a longer project duration of 17 days, and contribute to 70% more CO2 emissions while generating 737 m3 of spoil disposal.