Overburden

Drilling System

The overburden drilling system revolutionises the process of creating stable foundations in challenging ground conditions. Utilising a percussive drilling method, this system efficiently advances a durable steel casing through layers of overburden soil.

By effectively casing the pile as it progresses, the system ensures the integrity of the pile shaft and prevents collapse or contamination from surrounding materials. This enables the seamless transition to the stable rock strata beneath, facilitating the formation of a rock socketed pile. As a result, structures can be securely anchored in even the most difficult terrain, providing reliable support and stability for a wide range of construction projects.

WHAT THEY’RE USED FOR

Overburden Drilling System is an approach to pile construction tailored for demanding ground conditions. This innovative technique encompasses percussive drilling and casing methodologies, offering a versatile solution for navigating through challenging ground conditions. Whether confronted with soils consisting of cobbles, boulders, or layered rock formations, Overburden Drilling System excels in maintaining efficiency and structural integrity.

Its adaptability extends to traversing mine workings and fractured or laminated rock, making it a preferred choice for projects requiring robust foundation solutions. By seamlessly integrating drilling and casing processes, Overburden Drilling System ensures precise pile placement and stability, even in the most inhospitable environments, facilitating the successful completion of diverse construction projects.

THE PROCESS

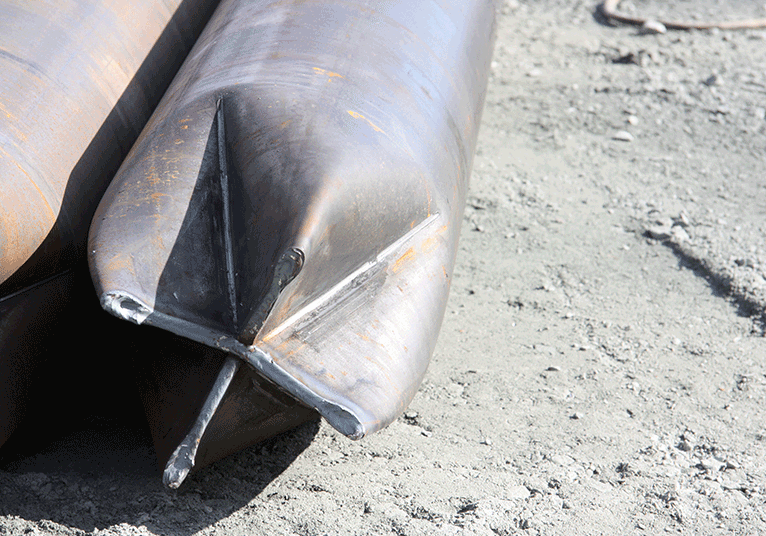

Overburden Drilling System represent a sophisticated method of foundation construction, characterised by their robustness and adaptability to various ground conditions. The process commences with the insertion of a steel casing into the ground, achieved through a combination of drilling and hammering techniques (rotary-percussive). This task is executed using a powerful down the hole hammer and over reaming drill bit, renowned for its ability to penetrate through most obstructions with relative ease, ultimately reaching solid rock formations. Once the casing reaches the desired depth, the drilling operation can transition seamlessly into the rock, creating an open hole for further reinforcement.

Subsequently, concrete is poured into the borehole, filling the void, and providing structural stability and allowing the transfer of load from the structure through the overburden and into bedrock . To enhance its structural capacity, a steel reinforcing cage is installed within the concrete mass. At this stage, the steel casing can either be extracted from the ground, leaving behind a reinforced concrete column, or it can be left in place, depending on the project requirements and geological considerations.

This process ensures the creation of durable and reliable foundation elements capable of withstanding the demands of various construction projects, from infrastructure developments to high-rise buildings. The versatility and effectiveness of Overburden Drilling System makes them a preferred choice for engineers and contractors seeking efficient and resilient foundation solutions in challenging ground conditions.

WHY USE Overburden Drilling System?

- Suitable for all soil types

- Ability to drill through most obstructions and socket into rock

- Can support high loads

- Bespoke geotechnical drawings

- Minimum vibration

- Various diameters available

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.