CLIENT

Integrated Health Projects, a JV between VINCI Building and Sir Robert McAlpine

SCOPE OF WORKS

PROJECT BRIEF

Roger Bullivant Limited (RBL) was approached by Integrated Health Project (IHP), a joint venture between VINCI Building and Sir Robert McAlpine, to support the construction of a new 500-space car park for Barts Health NHS Trust. This project marks the initial phase of a major regeneration of the existing hospital facilities.

RBL was tasked with reviewing the initial loadings provided by WSP Consulting and developing a tailored piling solution to support the structure effectively. As part of our scope, RBL proposed and delivered a Continuous Helical Displacement (CHD) piling solution, ensuring a robust and efficient foundation system for the project.

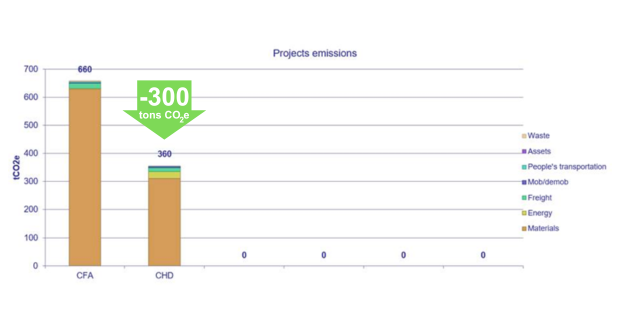

A Continuous Flight Auger (CFA) pile would generate 660 tCO2e compared with RBL’s CHD pile alternative which generated 360 tCO2e meaning an overall saving of -300 tCO2e.

KEY ISSUES

SOLUTION

- RBL designed and installed 300/600 CHD piles within a five-week program, significantly reducing transport movements, minimising spoil removal, and decreasing concrete deliveries compared to traditional methods. This approach streamlined the construction process, enhancing efficiency while minimising environmental impact.

- The existing ground conditions were typical for the area, consisting of up to 1.5m of made ground, followed by 1.0m of head deposits composed of sand and clay particles. Below this, London Clay formation extended to a maximum depth of 35.0m below ground level (bgl), providing a stable foundation for the piling solution.

- RBL designed the piles in accordance with Eurocode safety factors, ensuring they could accommodate the required load capacities. The 300/600mm CHD piles were designed to support varying compression and tension loads. To transfer these loads efficiently, the piles required 1350mm centre-to-centre spacing.

- Additionally, 400/700 CHD piles were installed to support higher load requirements, with higher compression capacities and tension loads. These larger piles required 1650mm center-to-center spacing to ensure structural stability.

- Thanks to favourable working conditions and smooth concrete deliveries, the piling works were completed in just 15 days, significantly ahead of schedule. This accelerated timeline allowed the client to bring their overall program forward, optimising project efficiency. In total, RBL installed 268 No. CHD piles, covering 3,380 linear meters, with an average pile depth of 12.6m.

- Utilising this technique, combined with good working conditions provided by the client, and the management of logistics ensured prompt concrete deliveries.