UNDERPINNING

Engineers and contractors can address foundation challenges with greater precision and efficiency, leading to minimised downtime and reduced costs. This approach offers a versatile solution for a wide range of structures, from residential homes to commercial buildings, allowing for seamless integration into ongoing renovation or construction projects.

Underpinning stands as a reliable method for increasing the structural capacity of foundations, whether they are currently incapable of supporting an existing structure or required to perform with additional loads for example if a building is altered or extended. This technique achieves its objective by redistributing or transferring the loads from the foundation to more competent ground, effectively minimising any potential settlement. Serving as a cost-effective alternative to traditional mass concrete underpinning methods, mini pile underpinning offers several advantages, notably by negating excavation risks such as the disposal of contaminated soils, manual handling and working in confined spaces.

WHAT THEY’RE USED FOR

Underpinning is typically employed during building refurbishments or extensions to existing structures. This method can also be utilised where original foundations exhibit signs of distress, either due to age, changes in soil or groundwater conditions, or alterations in the structure's usage over time.

The decision to undertake underpinning is often prompted by various factors, including visible signs of foundation instability, such as cracks in walls or floors, uneven settlement, or structural movement. These indicators signal the need for intervention to prevent further deterioration and ensure the long-term stability and safety of the building.

Furthermore, changes in soil conditions, such as subsidence or soil erosion, can compromise the integrity of existing foundations, necessitating reinforcement through underpinning. Similarly, alterations in the usage of a structure, such as increased load-bearing requirements or modifications to its configuration, may exceed the capacity of the original foundations, warranting additional support to accommodate the new demands.

THE PROCESS

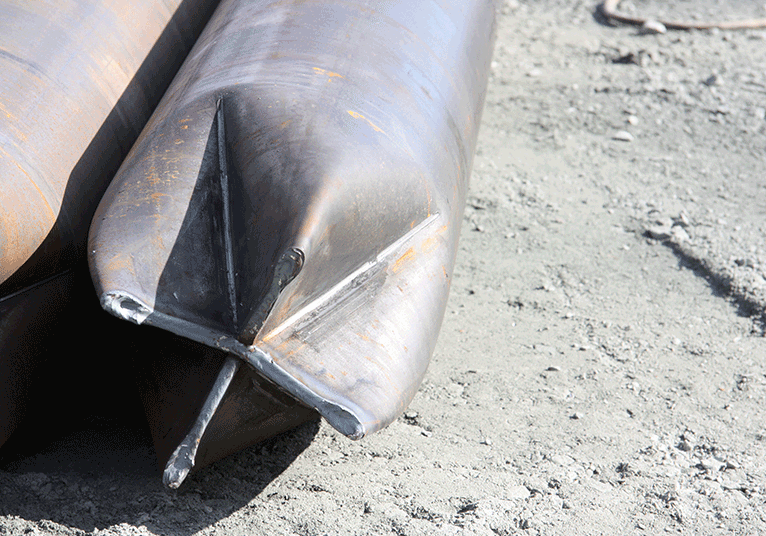

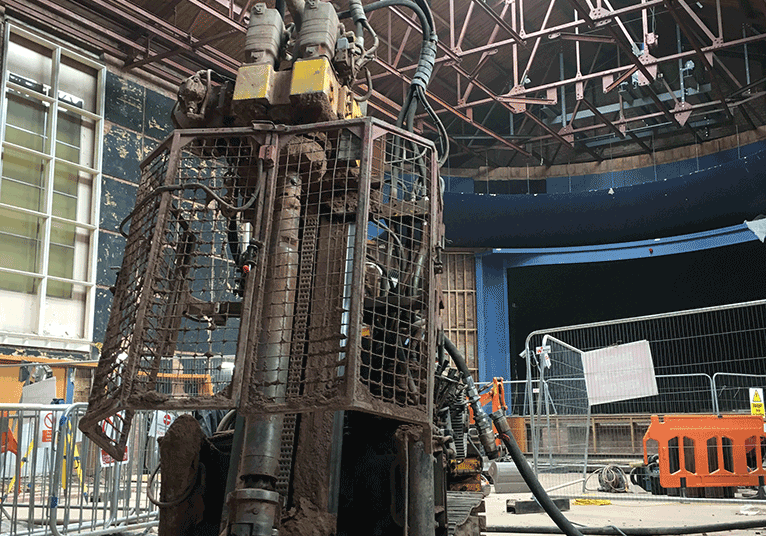

Utilising mini piles for underpinning offers a versatile and effective approach to stabilising existing structures, with various methods tailored to specific project requirements. These solutions typically incorporate a combination of mini piles, needle beams, and rafts, reinforcing the foundation and mitigating structural movement.

In situations where low vibration is a critical requirement, a jack pile system may be employed in conjunction with rafts or ground beam systems. This approach minimises ground disturbance and ensures minimal disruption to the surrounding environment, making it particularly suitable for sensitive sites or densely populated areas.

WHY USE Underpinning?

- Suitable for indoor and outdoor construction

- Extensive in-house fleet capabilities

- Bespoke geotechnical drawings

- Cheaper and quicker alternative to mass concrete underpinning

- Solutions where zero vibrations are required

EXAMPLE UNDERPINNING PROJECTS

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.