DRIVEN PRECAST

CONCRETE PILES

Driven Precast Concrete Piles are a versatile, cost-effective, and efficient deep foundation solution and are suitable for a wide range of ground conditions.

Our Precast Concrete Piles are designed and manufactured in-house in varying segmental lengths which are joined to achieve the overall required pile lengths to minimize waste on site and maximise installation flexibility.

RBL boasts an extensive fleet of bespoke, in-house designed, piling rigs specified to optimise site efficiency. These rigs offer lower bearing pressures than many ‘off-the-shelf rigs’ and ensure a streamlined construction process, offering both practicality, effectiveness, and cost efficiency.

WHAT THEY’RE USED FOR

Whether supporting the structural needs of residential dwellings or supporting an embankment for a new road, Driven Precast Concrete Piles has a lot to offer as a reliable and widely applicable solution. These piles can be found across a diverse range of sectors, ranging from housing and commercial developments to industrial buildings and even artistic installations. Their use also extends to civil engineering/infrastructure, making them suitable for countless projects, including bridges, embankment support, power, and transmission towers, as well as in the railway sector.

This pile type is commonly used to support ground beams, pile caps, building slabs, or in conjunction with raft foundations or load transfer platforms. Their many benefits compared to other piling types make them a preferred choice.

Driven Precast Concrete Piles are especially well suited to poor soils overlying better ground conditions, or overall weaker soil profiles. They are often much quicker to install than other pile types and permit quicker commencement of follow-on works, as well as a reduction in waste generated on site. They deliver a quality product, as they are manufactured in a controlled factory environment, and come in a range of sizes and lengths to suit the project.

Driven Precast Concrete Piles are ideal when used in conjunction with our Precast Concrete Beaming System, RBeam.

THE PROCESS

Driven Precast Concrete Piles are available in different segmental lengths, allowing for the installation of single or connected sections, which is advantageous in varying ground conditions. The driving force behind these piles is a top-driven hydraulic “quiet” hammer, which installs the pile using a percussive action to the required pile toe level. The lead pile section is pitched, and then subsequent pile sections are added as the pile progresses below ground, until the necessary length or resistance is achieved. The pile can then easily be cropped down by the follow-on trade contractor and connected to the substructure.

What sets Driven Precast Concrete Piles apart is their displacement nature, resulting in zero spoil generation from pile arisings. This not only streamlines the construction process and is advantageous for follow-on works, but also minimises the need for additional traffic movements, as would be common with the delivery of ready-mix concrete and costly removal of spoil from replacement/auger pile systems. This more sustainable approach also contributes to overall efficiency, cost-effectiveness, and minimising the foundation construction program.

WHY USE Driven Precast Concrete Piles?

Saves time

Cost-effective

Zero spoil

Immediate follow-on construction

Quiet installation

Ideal for environmentally sensitive areas

Manufactured in-house

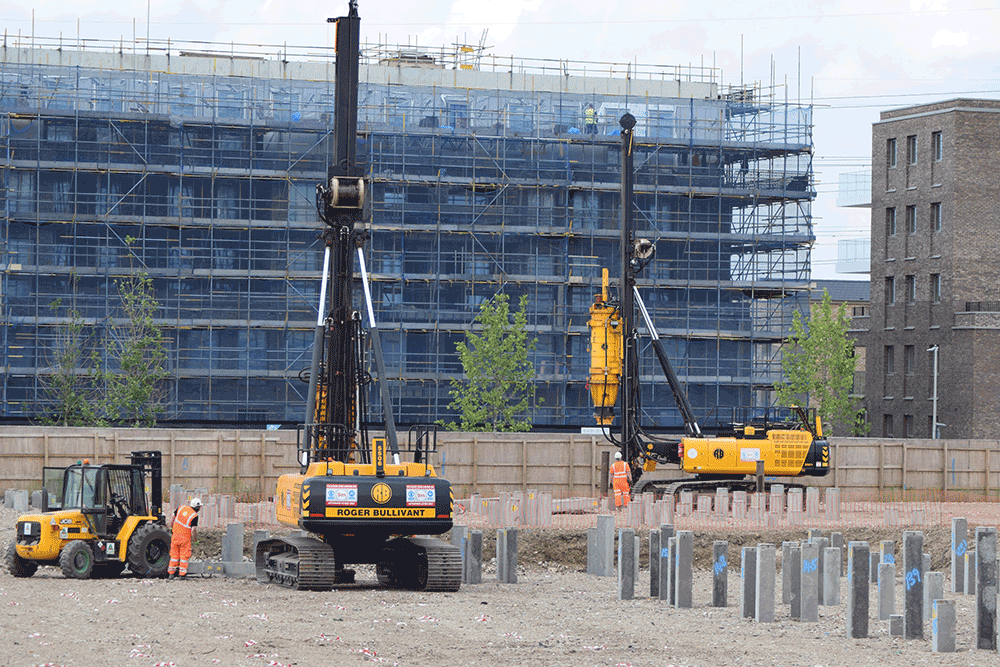

EXAMPLE Driven precast

concrete Piling PROJECTS

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.