DYNAMIC

COMPACTION

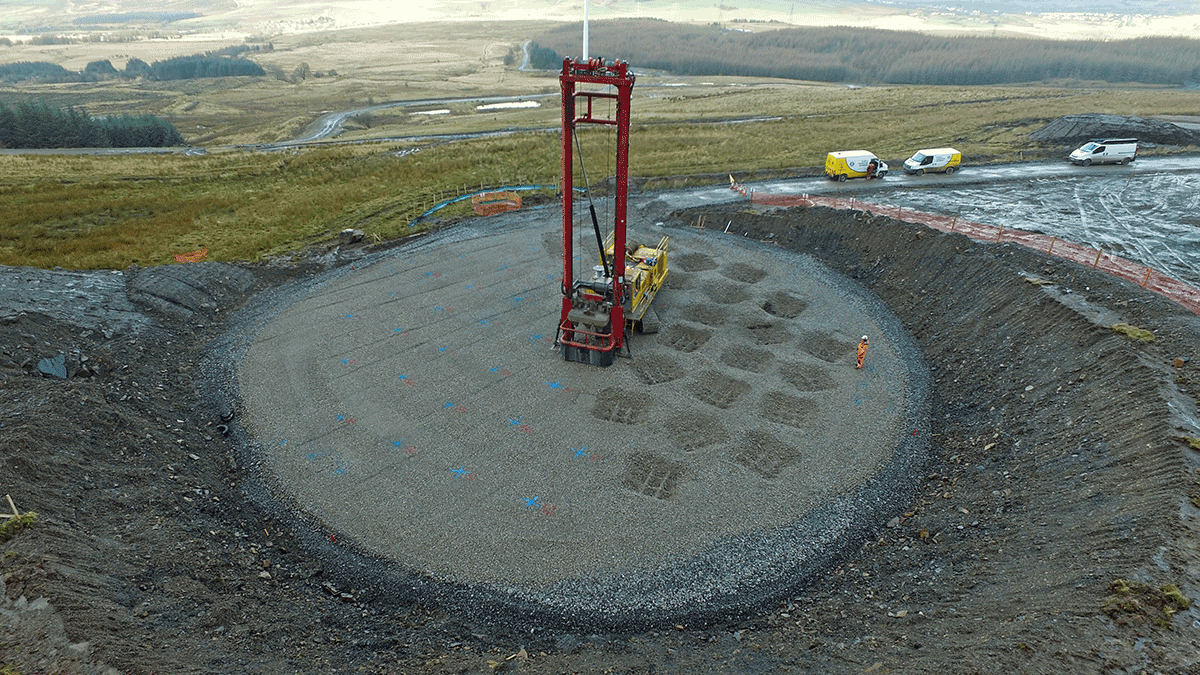

Dynamic compaction is a method used to increase the density of the in situ soils and to improve the load bearing capacity of the ground. The process involves repeatedly dropping a 12-tonne weight at predetermined grid pattern to achieve the required energy input.

WHAT THEY’RE USED FOR

Dynamic compaction is a highly sustainable ground improvement technique which produces zero spoil. This method can be used for the treatment of industrial warehouses, port and airport platforms, roads and railway embankments, heavy storage tanks, nonorganic heterogeneous fill or obstructed sites, and soils that are susceptible to liquefaction.

This method is extremely economical and is ideal for large sites where obstructions preclude vibro techniques.

THE PROCESS

The 12000 series drop weights are interchangeable and special shaped weights can be used depending on the application and site-specific ground conditions.

The ground is repeatedly subject to ground tamping using a heavy concrete weight, from a controlled height of up to 12 metres high at predetermined grid pattern. Typically, the ground is treated between two to five passes depending on the ground conditions.

WHY USE Dynamic Compaction (NRG)?

High production rate

Ideal for contaminated or obstructed sites

Alternative to vibro techniques

Reduced settlement

Increased bearing capacity

Improves soil conditions and strength

EXAMPLE DYNAMIC

COMPACTION PROJECTS

Sorry, we couldn't find any posts. Please try a different search.

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.