Carbon-efficient ground improvement with predictable settlement control

Controlled Modulus Rigid Inclusions (CMRIs) are Roger Bullivant Limited’s advanced ground improvement method, intended to provide a designed solution to bridge the gap between Vibro Stone Columns and piled foundations. They provide high load-bearing capacity and settlement control in weak and compressible soils, delivering a sustainable, low-carbon alternative to traditional piling.

What Controlled Modulus Rigid Inclusions are used for

Designed to work in concert with bearing pressures rather than point loads, concrete inclusions are installed within the soil to create a composite foundation system supported by a designed load transfer platform (LTP). This structure limits settlement and works with the surrounding soil through skin friction and partial end bearing. Shallow foundations can then be built on the LTP and improved soils, reducing the need for heavily reinforced or underbuilt systems.

CMRIs are suited to low and mid-rise buildings, including high-density residential, commercial, retail, healthcare, industrial and infrastructure projects. The method provides reliable performance across varied soil profiles where traditional piling might be uneconomical or impractical.

How Controlled Modulus Rigid Inclusions are installed

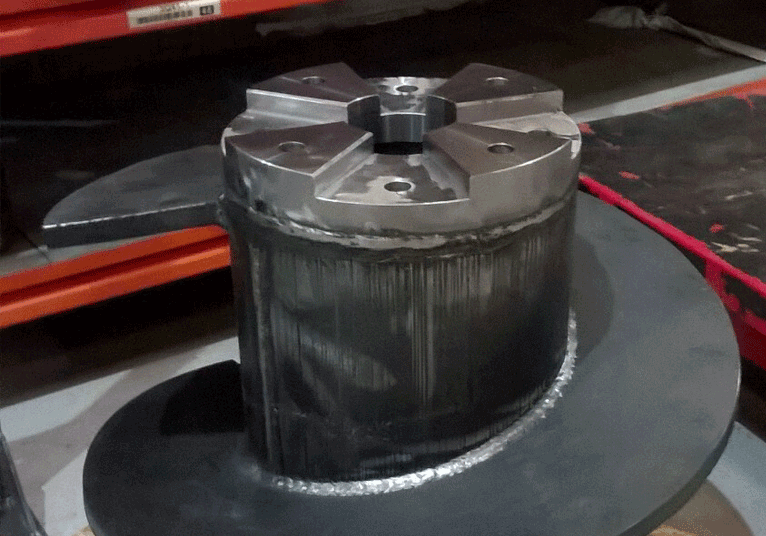

Rigid inclusions, typically 250–600mm in diameter, are installed using a displacement technique that penetrates to a design depth without soil extraction. Multiple inclusions are installed on a set grid to support the structural footprint.

Each operation is monitored in real time using purpose-built rigs with comprehensive instrumentation to ensure accuracy and traceability. Once formed, any residual surface arisings are removed. The aggregate load transfer platform is then constructed to a specified thickness and density before validation using plate load or zone loading tests prior to the main foundation construction begins.

Why choose Controlled Modulus Rigid (CMRI) Inclusions?

- Fast installation

- Efficient in cost and carbon emissions

- Minimal spoil

- Increases bearing capacity in weak soils under high loads

- Manages settlement in variable or weak soils.

- Adaptable to a wide range of foundation loadings and business sectors

- Designed load transfer platform ensures even load sharing with surrounding soils minimising differential settlement.

Engineering value into every project

CMRIs extend RBL’s foundation engineering capabilities, enabling our engineers to compare ground improvement and piling systems to achieve the most efficient, sustainable outcome. The goal is consistent: to deliver cost-effective, safe, and carbon-conscious foundations with predictable performance.

Sustainability and site impact

The technique uses eco-grout or low-carbon concrete and is classed as a displacement method, meaning minimal spoil generation. CMRIs offer rapid installation, low noise, and low vibration, making them ideal for sensitive or live environments such as urban developments and infrastructure sites. They are environmentally efficient foundations.

Digital, modern plant

RBL invests in advanced piling rigs with on-board instrumentation. Our teams can review live installation data to support decision making and quality control. We also use historic rig and test data to inform early estimates and reduce design risk. This digital thread supports consistency from tender stage through to delivery and beyond.

Early contractor engagement

Engaging RBL early unlocks the full benefits of CMRI. At concept or planning stage we can test alternatives, validate depths with targeted investigation and agree construction sequencing that streamlines follow-on works. The result is predictable cost, robust performance and a smoother path to site as well as efficient use of carbon emissions.

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and controlled modulus rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.