Continuous Helical Displacement (CHD) Piling

A sustainable, low-vibration foundation solution

Initially developed in the mid 1990’s Continuous Helical Displacement (CHD) piling, sometimes referred to as auger displacement piles, is a cast-in-situ technique that displaces soil laterally rather than extracting it. The result is minimal spoil, fewer lorry movements for removal and lower embodied carbon compared with traditional bored methods such as CFA piling. Installation is virtually vibration-free with low noise, which makes CHD well suited to constrained urban sites or sensitive assets.

What is CHD piling used for?

CHD is a versatile option across residential piling, commercial piling and infrastructure projects where clients want a clean, efficient piling method with reliable capacity. It performs well in a broad range of soils including loose to medium dense sands and gravels, and cohesive soils from soft silts to stiff clays. Where loads, access or programme dictate, our engineers will compare CHD with alternatives such as CFA piles or Driven Precast Concrete Piles to value engineer the best outcome.

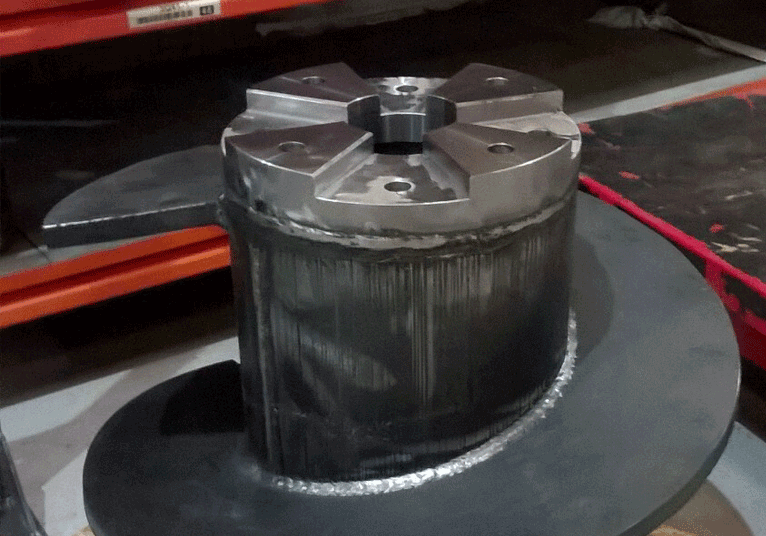

How CHD piles are installed

Our rigs use computer-controlled instrumentation for accuracy and traceability. A bullet-ended multi-flight tool is rotated into the ground to displace the soil. At design depth, concrete is pumped under pressure through the hollow stem as the tool is reverse-rotated and withdrawn. This forms a continuous helical fin surrounding the shaft with strong and efficient load transfer capabilities. Reinforcement cages or bars are then placed immediately after concreting. Minimal surface spoil is cleared to complete the pile.

Why choose CHD piling?

- Minimal spoil: typically less than 0.3–0.5 m³ per pile, which reduces disposal and transport requirements.

- Low vibration and reduced noise: suitable for sensitive environments and live assets.

- Programme efficiency: fast installation with modern rigs and automated monitoring.

- Sustainability profile: lower embodied carbon potential than like-for-like bored alternatives.

- Broad ground compatibility: effective in both cohesive and granular soils.

- Very high load transfer efficiency: This leads to shorter, more carbon efficient piles.

Engineering value into every project

CHD piling is often part of a wider foundation strategy. RBL’s ground engineers assess geotechnical conditions, loading and site constraints before recommending the most effective approach. We routinely value engineer specifications from CFA to CHD where it brings advantage.

The objective is clear: reduce spoil and carbon while improving programme delivery and maintaining performance. As RBL is not tied to one system or another we have the flexibility to propose the most suitable solution for the project.

Sustainability in practice

Reducing spoil is only the start. The piles are also comparatively shorter than CFA or bored piles leading to fewer transport movements for removal mean lower emissions on site.

We also specify low-carbon concrete mixes with GGBS replacement where design allows, and use recycled reinforcement from approved suppliers. Many tier one clients now set ambitious embodied carbon targets. CHD helps them meet those goals without compromising buildability.

Digital, modern plant

RBL invests in advanced piling rigs with on-board instrumentation. Our teams can review live installation data to support decision making and quality control. We also use historic rig and test data to inform early estimates and reduce design risk. This digital thread supports consistency from tender stage through to delivery and beyond.

Early contractor engagement

Engaging RBL early unlocks the full benefits of CHD piling. At concept or planning stage we can test alternatives, validate depths with targeted investigation and agree construction sequencing that streamlines follow-on works. The result is predictable cost, robust performance and a smoother path to site as well as efficient use of carbon emissions.

Other piling methods from Roger Bullivant Limited

Roger Bullivant Limited provides a full suite of piling and ground engineering techniques, including:

- Driven precast concrete piles

- Precast concrete piles, precast concrete ground beams and prefabricated foundations

- CFA piling, CHD Piling, CDA piling, CHAD piles, SFA piles and overburden drilling system piles

- Driven tubular steel piles

- Vibro stone columns and rigid inclusions

We deliver to BS EN and ISO standards with CE-marked products. RBL has a multi-year RoSPA Gold record. Our in-house manufacturing, regional delivery model and integrated design capability provide dependable quality and supply resilience.

These alternatives allow us to design and deliver foundation systems tailored to every site, load requirement and budget.